In modern construction, where deadlines are tight and productivity is a competitive differentiator, having solutions that optimize execution time without compromising safety is essential. Piston tools, also known as indirect-acting powder-actuated fastening tools, are key players in this scenario.

What are piston tools?

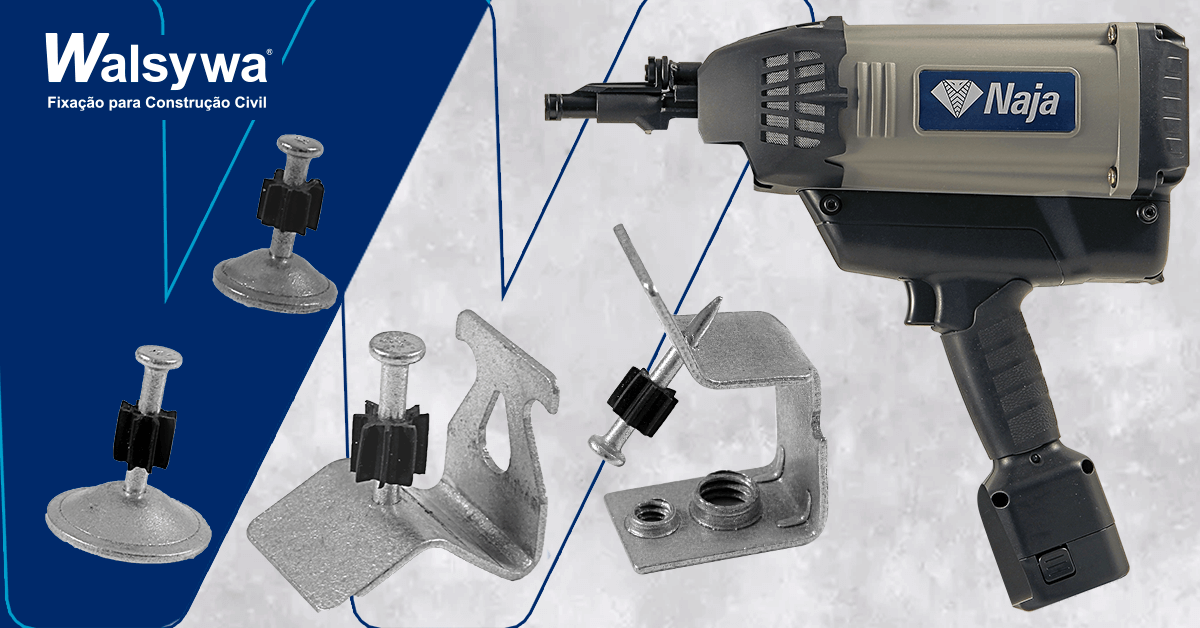

They are tools that use magazinated gunpowder cartridges to make fast and secure fixings in substrates such as solid concrete and structural steel. The force generated by the deflagration of the cartridge drives the piston, which in turn hits the pin or fastener, fixing it directly to the base material, eliminating the use of drills and dowels.

Where to use piston tools?

Piston tools are ideal for:

- Fixing metal profiles, rails, guides and drywall structures to concrete;

- Installing electrical boxes, cable trays and supports in concrete or steel;

- Light applications requiring high productivity and serial repetition;

- Environments with limited access to electricity, as the tool is self-contained.

Advantages of gunpowder fixing:

• Fast application — saves time and labor;

• Reduction of steps — no pre-drilling required;

• High mechanical performance — reliable fixings for light loads;

• Mobility on site — light and portable tools, ideal ofor dynamic constuction work.

Discovers Walsywa´s piston tools

Walsywa is a brasilian benchmark in construction fasteners and offers a complete range of piston tools for different applications:

This entry-level tool, with its ergonomic design and safety system against accidental release, like all piston tools, provides precise fastenings with less operator effort.

Cost-effective indirect fastening tool. Ideal for light applications. Compact, easy to use and with excellent performance. It has a double handle for greater operator comfort and a noise reducer. It also has a power regulator, providing greater control over pin penetration.

Classic model of the range, versatile and resistant. Compatible with different types of pins and cartridges. It has a power regulator, providing greater control over the penetration of the pin

More robust, it is suitable for more intense and frequent applications, requiring less maintenance if used correctly. It combines strength, durability and comfortable handling. It has a power regulator, providing greater control over the penetration of the pin.

Conclusion

Walsywa’s piston tools are intelligent solutions for those seeking productivity, safety and efficiency when fixing structures. Whether for residential, commercial or industrial work, we have the ideal equipment for your challenge.

Get in touch via WhatsApp and secure the best conditions on the market now!