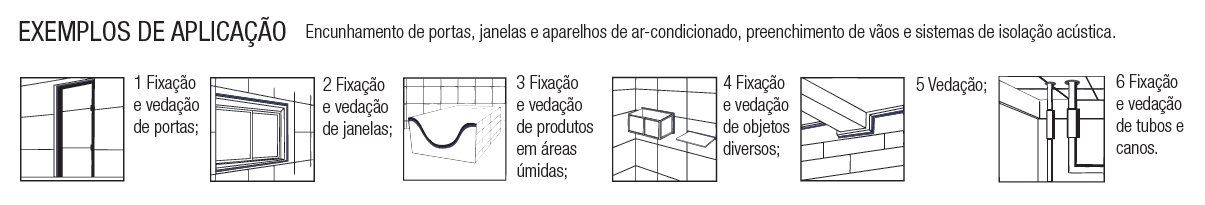

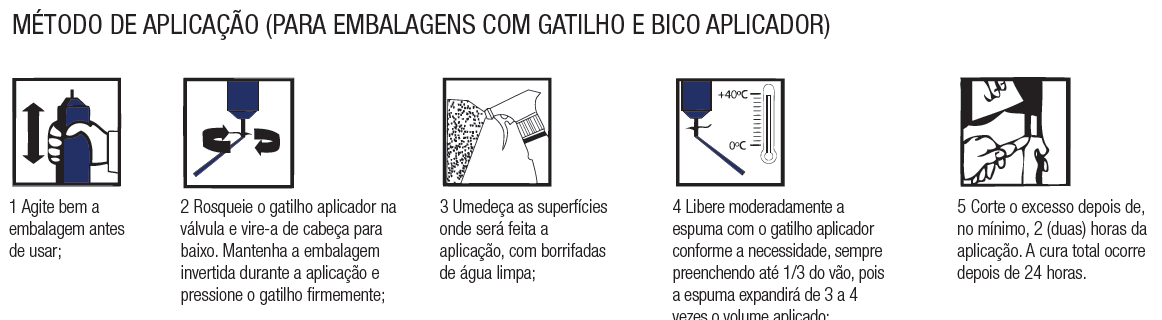

Walsywa Polyurethane Foam is indicated for domestic or professional applications in the installation of doors, windows, air conditioners, filling expansion joints and empty spaces, in addition to minor repairs and masonry wedging. Due to its easy handling, great performance, great economy and safe application, Walsywa Polyurethane Foam facilitates the user’s daily work. Drying is quick and, after that, it allows jobs such as sawing, cutting, sanding, plastering and even painting. It is water and heat resistant but should not be exposed to direct sunlight. For this, it is necessary to have a coating.

Menu

Concrete

Concrete Hollow Block

Hollow Block Rock

Rock Drywall

Drywall Cement Board

Cement Board Wall Panel

Wall Panel Wood

Wood OSB

OSB Structural Steel

Structural Steel Metal Tile

Metal Tile Aluminum

Aluminum Guides and amounts

Guides and amounts