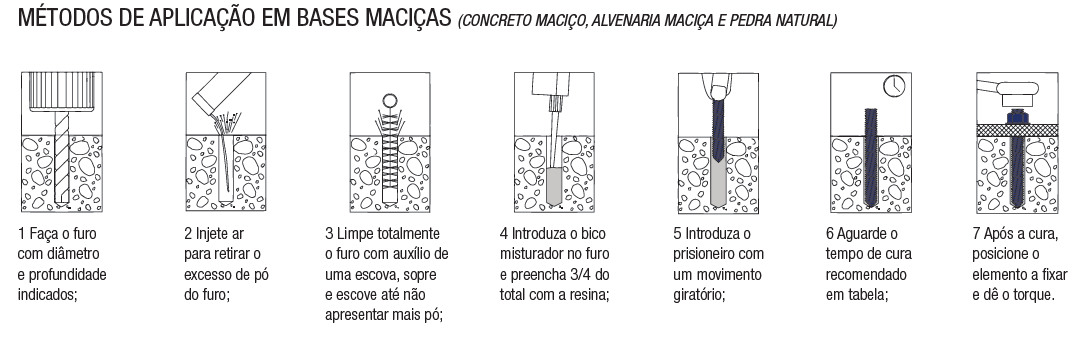

The WQE 500 Plus Chemical Injection Anchor Bolt is a two-component epoxy bonding system. It is a product with structural characteristics and, when used in conjunction with a threaded bar or construction rebar, it serves various situations of fastening to solid bases (solid concrete, solid masonry, and natural stone) of high responsibility, such as starters and consoles. It cures slowly and withstands very high loads, whether static or dynamic.

Menu

Concrete

Concrete Hollow Block

Hollow Block Rock

Rock Drywall

Drywall Cement Board

Cement Board Wall Panel

Wall Panel Wood

Wood OSB

OSB Structural Steel

Structural Steel Metal Tile

Metal Tile Aluminum

Aluminum Guides and amounts

Guides and amounts