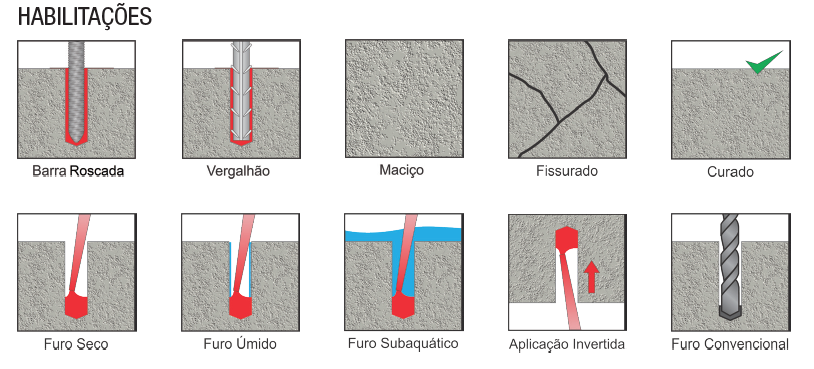

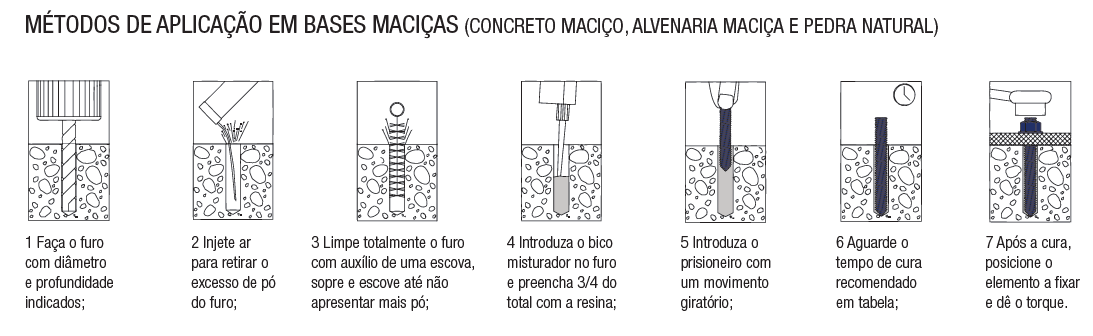

The WQE 600 Chemical Injection Anchor Bolt is a two-component epoxy bonding system. It can be used with rebar or threaded bar in cracked concrete, non-cracked concrete, natural stones, and solid masonry. The WQE 600 is suitable for structural applications, including in extreme environments such as in areas with the presence of chlorine or coastal regions.

Menu

Concrete

Concrete Hollow Block

Hollow Block Rock

Rock Drywall

Drywall Cement Board

Cement Board Wall Panel

Wall Panel Wood

Wood OSB

OSB Structural Steel

Structural Steel Metal Tile

Metal Tile Aluminum

Aluminum Guides and amounts

Guides and amounts